E-Xay cung cấp toàn bộ phạm vi của PCD tẩy trống và PCDN tẩy trống cho dụng cụ cắt mục đích. Đường Kính lớn nhất củaPCD tẩy trống vàPCDN tẩy trốngCó sẵn có thể là 55mm. Của chúng tôiPCD tẩy trống vàPCDN tẩy trốngCung cấp cao mặc sức đề kháng khả năng và độ hoàn thiện cao bề mặt.

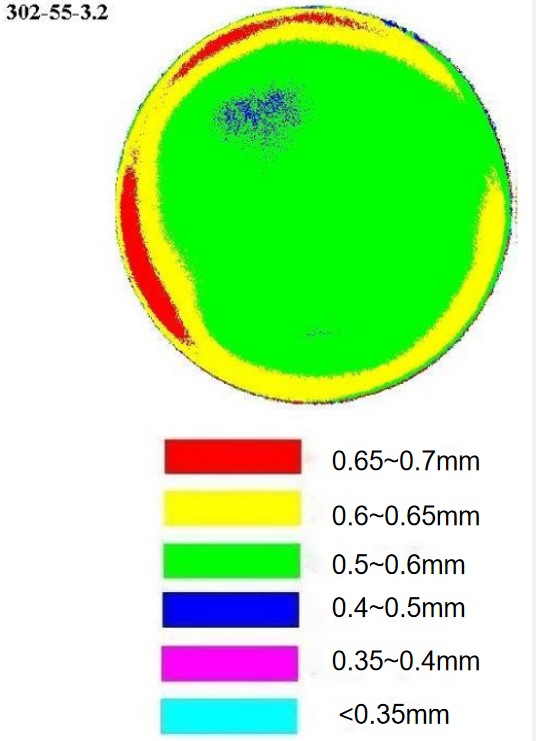

Chúng ta có hoa cài đặt Laser máy cắt và bề mặt cạo vôi và hoàn thiện máy móc để cung cấp đầy đủ dịch vụ cho PCD. Với công nghệ kiểm tra máy của SEM, C-SCAN, Tia X Diffractometer v. v. chúng ta có hoa áp dụng Kiểm tra Chất Lượng nghiêm ngặt quá trình.

Kim loại màu và hợp kim: Nhôm/Xám sắt Composite, đồng, Nhôm...

Nonmetallic Chất liệu: gốm sứ, nhựa, cao su, ván dăm...

| Sản phẩm | Kim Cương Nội Dung (Tập %) | Sản phẩm Tính Chất | Ứng dụng | |||

| ET02 | ≥ 92 | Rất tốt phóng điện gia công, tướng cuộc sống tốt hơn, khả năng chịu nhiệt và chịu va đập. | Superfinishing, xuất sắc bề mặt xử lý chất lượng cho đồng, đồng, nhôm, magiê, magiê nhôm hợp kim, nhựa, kim loại quý, v. v. | |||

| ET05 | ≥ 92 | Rất tốt phóng điện gia công, tướng cuộc sống tốt hơn, khả năng chịu nhiệt và chịu va đập. | Superfinishing, xuất sắc bề mặt xử lý chất lượng cho đồng, đồng, nhôm, magiê, magiê nhôm hợp kim, nhựa, kính plexiglas, v. v. | |||

| ET10 | ≥ 95 | Điện tốt xả gia công, tuổi thọ lâu dài, tốt hơn khả năng chịu nhiệt và chịu va đập. | Mỹ gia công, rất tốt bề mặt xử lý chất lượng, cho Hợp kim nhôm (Si nội dung <12%), hợp kim đồng, tổng hợp chế biến gỗ, độ chính xác cao chịu mài mòn corbelled thiết bị, v. v. | |||

| ET25 | ≥ 95 | Điện tốt xả gia công, tuổi thọ lâu dài, tốt hơn khả năng chịu nhiệt và chịu va đập. | Sử dụng cho Composite, sàn gỗ công nghiệp, phi kim cứng và giòn vật liệu, cacbua hợp kim, than chì và Graphite Composite, nhôm Silicon hợp kim (Si nội dung> 12%), khác cao chịu mài mòn vật liệu, chẳng hạn như gốm sứ, cacbua, v. v. | |||

| ET35 | ≥ 95 | Điện tốt xả gia công, tuổi thọ rất cao, khả năng chịu nhiệt tốt và khả năng chịu va đập. | Sử dụng cho nhựa, vật liệu tổng hợp, chất xơ, chất tăng cường nhựa, mật độ cao tăng cường ban, silicon nhôm hợp kim và cao khác chịu mài mòn vật liệu. | |||

| ET302 | ≥ 95 | Điện tốt xả gia công, tuổi thọ lâu dài, tốt hơn khả năng chịu nhiệt và chịu va đập. | Sử dụng cho Composite, sàn gỗ công nghiệp, phi kim cứng và giòn vật liệu, cacbua hợp kim, than chì và Graphite Composite, nhôm Silicon hợp kim (Si nội dung> 12%), khác cao chịu mài mòn vật liệu, chẳng hạn như gốm sứ, cacbua, v. v. | |||

| Kích thước hạt | Ứng dụng | Cao cấp | Đường kính | Tổng độ dày | Kim Cương độ dày mặt bàn | Chế biến gỗ | Gia công kim loại | Dẫn điện |

| 0.85μm | Siêu mịn micron cấu trúc tuyệt vời bề mặt hoàn thiện yêu cầu, | ET085 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ |

|

|

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ |

|

|

|||

| 2μm | Tốt cho bề mặt hoàn thiện | ET02 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 |

|

|

√ | |||

| 5μm | ET05 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ | |

| 10μm | Mục đích chung, cân bằng Hiệu suất cắt và cuộc sống | ET10 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|||

| 25μm | Tốt khả năng sản xuất, cao Sĩ % AL hợp kim. | ET25 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|||

| 302μm | ET302 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ | √ | |

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|||

| 35μm | ET35 | 45 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ | √ |

|

|

| 55 | 1.6/2.0/3.2 | 0.5 ± 0.15 | √ |

|

|

PCBN gồm CBN và Chất Kết Dính. Nó được sản xuất ở áp suất cao và nhiệt độ cao. Đô thị này có thành tích xuất sắc trong độ cứng, mặc sức đề kháng, nhiệt độ ổn định.

Ứng dụng: cho cứng vật liệu bằng sắt (thép cứng, gang, nhiệt độ cao hợp kim, HSS, luyện kim bột kim loại, Ni-Cr hợp kim...

E-Xay cung cấp hai loạt PCBN:

1) chắc chắn CBN

2) CBN với Cacbua Vonfram hỗ trợ.

PCBN và SBN Cao Cấp

| Cao cấp | CBN nhám (μm) | CBN nội dung (Tập %) | Xử lý cách | Ứng dụng |

| SBN95Z1 PCBN95Z1 | 20 、 30 | 0.95 | Liên tục cắt lớn cổ loại bỏ | Cho Thô xử lý Màu Xám Gang, Ướp Lạnh Gang, Bột Thiêu Kết Hợp Kim. |

| SBN90Z PCBN90Z | 10 、 15 | 0.9 | Liên tục cắt lớn cổ loại bỏ | Cho Thô quá trình và bán hoàn thiện chế biến chịu mài mòn gang, nốt sần đúc Sắt V. v. |

| SBN90Z2 PCBN90Z2 | 10 、 15 | 0.9 | Liên tục cắt lớn cổ loại bỏ | Cho thô chế biến và bán xử lý hợp kim gang, cao Nickel Chrome, cao sắt mạ crôm và ướp lạnh Thép với độ cứng HRC45-50. |

| SBN80G | 3 、 5 | 0.8 | Liên tục cắt với Trung Bình cổ loại bỏ | Cho thô chế biến và bán xử lý hợp kim gang, cao Nickel Chrome, cao sắt mạ crôm và ướp lạnh Thép với độ cứng HRC45-50. |

| SBN70G PCBN70G | 3 、 5 | 0.7 | Liên tục cắt nhỏ cổ loại bỏ | Để hoàn thiện các ướp lạnh thép và nhiệt độ cao hợp kim với HRC45-55. |

| SBN60G | 1 、 3 | 0.6 | Liên tục cắt nhỏ cổ loại bỏ | Để hoàn thiện và siêu-Hoàn thiện ướp lạnh thép với HRC55-62 như thép chịu lực, thép dụng cụ, khuôn Thép, đồng hồ đo thép và HSS. |

| SBN55G1 PCBN55G1 | 1 、 3 | 0.55 | Nhẹ không liên tục và liên tục cắt nhỏ cổ loại bỏ | Để Hoàn Thiện và siêu-Hoàn thiện ướp lạnh thép với HRC55-65, giống như thép chịu lực, thép dụng cụ, khuôn Thép, đồng hồ đo thép và HSS. |

| CHI TIẾT KỸ THUẬT | D (Đường Kính) (mm) | T (Độ Dày)(mm) | T (CBN phần độ dày)(mm) | PCBN55G1 | PCBN70G | PCBN90Z | PCBN90Z2 | PCBN95Z1 |

| Ф45 × 1.2 × 0.6 | 45 | 1.2 ± 0.05 | Năm 0.5-0.8 | √ | √ | √ | √ | √ |

| Ф45 × 1.6 × 1.0 | 45 | 1.6 ± 0.05 | Năm 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45 × 3.2 × 1.0 | 45 | 3.2 ± 0.05 | Năm 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45 × 3.8 × 1.0 | 45 | 3.8 ± 0.05 | Năm 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45 × 4.5 × 1.0 | 45 | 4.5 ± 0.05 | Năm 0.9-1.2 | √ | √ | √ | √ | √ |

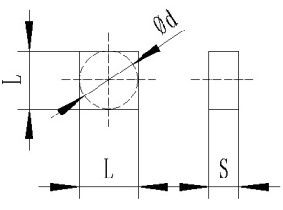

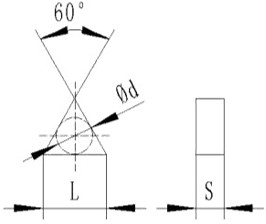

| Chi tiết kỹ thuật | Kích thước (mm) | ISO | Mã | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 9.85 × 3.4 | 9.85 | 9.85 | 3.4 | SNMN090300 | √ | √ | √ | √ | √ | √ | √ |

| 9.85 × 5 | 9.85 | 9.85 | 5 | SNMN090400 | √ | √ | √ | √ | √ | √ | √ |

| 13 × 5 | 13 | 13 | 5 | SNMN120400 | √ | √ | √ | √ | √ | √ | √ |

| 16.2 × 8.2 | 16.2 | 16.2 | 8.2 | SNMN150700 | √ | √ | √ | √ | √ | √ | √ |

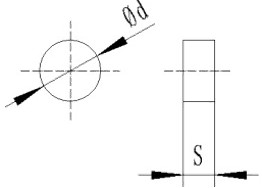

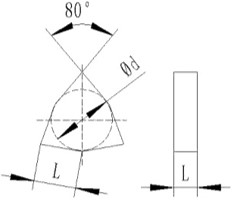

| Chi tiết kỹ thuật | Kích thước (mm) |

|

ISO | Mã | |||||||

|

|

Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 6.7 × 5 |

|

6.7 | 5 | RNMN060400 | √ | √ | √ | √ | √ | √ | √ |

| 9.85 × 3.4 |

|

9.85 | 3.4 | RNMN090300 | √ | √ | √ | √ | √ | √ | √ |

| 9.85 × 5 |

|

9.85 | 5 | RNMN090400 | √ | √ | √ | √ | √ | √ | √ |

| 13 × 5 |

|

13 | 5 | RNMN120400 | √ | √ | √ | √ | √ | √ | √ |

| Chi tiết kỹ thuật | Kích thước (mm) | ISO | Mã | |||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | ||

| 9.85 × 5 | 9.85 | 9.85 | 5 | CNMN090400 | √ | √ | √ | √ | √ | √ |

| 13 × 5 | 13 | 13 | 5 | CNMN120400 | √ | √ | √ | √ | √ | √ |

| 13 × 8.2 | 13 | 13 | 8.2 | CNMN120800 | √ | √ | √ | √ | √ | √ |

| Chi tiết kỹ thuật | Kích thước (mm) | ISO | Mã | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 11.3 × 3.4 | 11.3 | 6.524 | 3.4 | TNGN110300 | √ | √ | √ | √ | √ | √ | √ |

| 16.8 × 5 | 16.8 | 9.699 | 5 | TNGN160400 | √ | √ | √ | √ | √ | √ | √ |

| Chi tiết kỹ thuật | Kích thước (mm) | ISO | Mã | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 9 × 5 | 9 | 13.1 | 5 | WNMN080400 | √ | √ | √ | √ | √ | √ | √ |

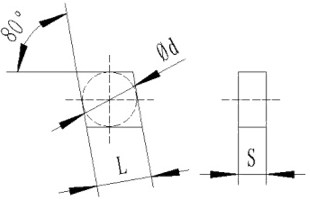

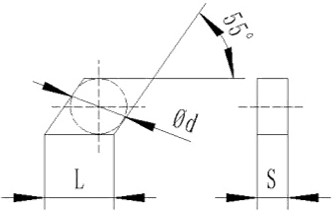

55 ° hình thoi

| Chi tiết kỹ thuật | Kích thước (mm) | ISO | Mã | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 11.3 × 5 | 11.3 | 9.256 | 5 | DNUN110400 | √ | √ | √ | √ | √ | √ | √ |

| 11.3 × 6.6 | 11.3 | 9.256 | 6.6 | DNUN110600 | √ | √ | √ | √ | √ | √ | √ |

| 15.8 × 6.6 | 15.8 | 12.943 | 6.6 | DNUN150600 | √ | √ | √ | √ | √ | √ | √ |